Custom Boxes & Custom Packaging | Design your own box

Custom printed boxes and die cut inserts inner corrugated packaging

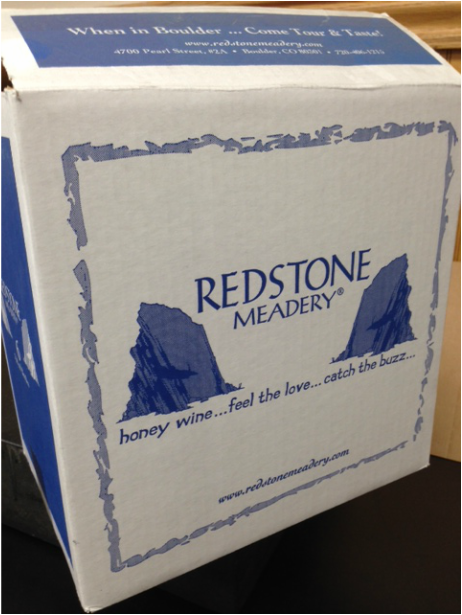

Big Valley Packaging can help you create your custom printed cardboard shipping boxes. We add your logo on shipping boxes with custom printing. It’s one of the best ways to create a brand identity for your company. Printed boxes help build brand recognition. With corrugated package printing your advertising follows your packages wherever they may go. Let your customers see your company name flexo color imprinted on your shipping boxes. Box manufacturing is to your specifications. Custom logo printed boxes available in single wall, double wall, and triple wall cardboard boxes.

Contact us with your artwork for price quotes and lead times.

Printed shipping boxes with flexo printing (1,000 min) is your standard industrial logo imprint. For smaller quantities of we recommend adding your logo with our custom printed labels.

Litho lamination printing (Minimum quantity 10,000) is a high end four 4 color process printing laminated boxes are also available.

Custom printed shipping boxes

Printed corrugated boxes (Minimum order 1,000 boxes)

Printed mailers

Custom printed high end retail litho laminated boxes (10,000 Minimum)

Printed healthcare boxes

Logo printers

Printed containers

Printed food boxes

Printed cardboard boxes

Custom box printing also available for chipboard folding cartons from medical devices to retail and food products. (Minimum quantity 1000 boxes for printing.)

Folding cartons for such items as cosmetic lotions, perfumes, and make up

Printed cartons for frozen foods and retail food products

Plastic corrugated boxes available

Custom Boxes & Custom Packaging Design your own box

Custom sized boxes made to order

RSC Regular slotted container shipping boxes for industrial packaging and shipping

RELF Roll end lock front mailers for shipping product orders such as clothing and apparel boxes

HSC Half slotted containers for pallet over packs that are large or heavy, used for exporting

Printed shipping boxes

Custom package creation services for inner and outer packaging

Automotive parts boxes printing

Die cut corrugated inserts, sleeves, sheets, & pads

Custom flexo printed boxes and corrugated package printing

Printed Gift Box

Wide selection of Flexo Printing Ink Colors

Beer Boxes

Printed healthcare medical boxes

Thicknesses Of Corrugated

E-Flute: 1/16" thick, 90 flutes per linear foot

B-Flute: 1/8" thick, 47 flutes per linear foot

C-Flute: 3/16" thick, 39 flutes per linear foot

A-Flute: 1/4" thick, 33 flutes per linear foot

A-Flute

A-flute is the original corrugated flute design and is the thickest. With it's thickness , A-flute provides the greatest cushioning properties for fragile products. Because A-flute offers excellent stiffness qualities and short column crush resistance, it has application across a broad range of customer uses.

Flutes per Linear Foot: 33, Thickness: 1/4"

C-Flute

C-flute is the most widely used flute size, commonly used for shipping cases. Often used for packaging glass products, dairy products, and furniture, C-flute offers good crushing resistance, good stacking strength, and highly acceptable printing properties. Very common, roughly 80% of corrugated containers are made of C-flute board.

Flutes per Linear Foot: 39-43, Thickness: 3/16"

B-Flute

With lower arch heights and more flutes per foot than A-flute material, B-flute contacts liners at a greater number of points. This additional support provides a stiff, flat surface for high quality printing and die cutting. B-flute offers excellent puncture and crush resistant properties, and consumes less warehouse space. Developed for packaging canned goods, B-flute is used for beverage trays, wrap-around blanks, glass-to-glass packs, and slipsheets. B-flute is also preferred for high speed, automatic packing lines as well as for pads, dividers, partitions, and other forms of inner packing.

Flutes per Linear Foot: 42-52, Thickness: 1/8"

E-Flute

Containing about 90 flutes per foot, E-flute has greater crush resistance and a relatively flat surface for high quality printing applications. The thin board profile of E-flute reduces outer box dimensions, and can help save storage space. Because of its thin profile, cushioning properties, and flat surface, E-flute offers a strong alternative for conventional paperboard folding cartons including boxes for cosmetics, fragile glass, and ceramic items, and delicate instruments.

Flutes per Linear Foot: 94, Thickness: 1/16"

BC-Flute Double Wall

A combination of B and C flute layers to create a double wall thickness box. This board can hold very large and heavy items.

Flutes 1 layer of B + 1 layer of C, Thickness: Double Wall

Edge Crush Test

Edge Crush Test is a method used to determine the "stacking" or "crushing" of corrugated board. The test is done to determine the force that will crush a container board standing on an edge. The ECT will determine the compression strength of the container made from the board.

Single wall 23 ECT Maximum Suggested Load Limit (lbs): 20

Single wall 26 ECT Maximum Suggested Load Limit (lbs): 35

Single wall 29ECT Maximum Suggested Load Limit (lbs): 50

Single wall 32 ECT Maximum Suggested Load Limit (lbs): 65

Single wall 36 ECT Maximum Suggested Load Limit (lbs): 75

Single wall 42 ECT Maximum Suggested Load Limit (lbs): 80

Single wall 44 ECT Maximum Suggested Load Limit (lbs): 95

Double wall 48 ECT Maximum Suggested Load Limit (lbs): 100

Double wall 51 ECT Maximum Suggested Load Limit (lbs): 120

Double wall 61 ECT Maximum Suggested Load Limit (lbs): 140

Printed wine boxes shipping cases

Cardboard Box Types

Regular Slotted Containers RSC

This is the most common shipping box style. All the flaps are the same length from the score to the edge. Ideal for everyday shipping small individual parts and merchandise.

Half Slotted Containers HSC

Half slotted containers are similar to RSC regular slotted containers except that they have only one set of flaps on one end. The opposite end of the box is open, which allows the box to slide over an item. Ideal for: large and heavy objects such as refrigerators and washing machines. Sometimes used in conjunction with wooden pallets or wood floater decks as an overpack.

Full Over Lap FOL

The outer flaps overlap the full width of the box making it especially resistant to rough handling because of the double layers of flaps. All flaps are the same depth, and their depth equals the width of the box. Ideal for: heavy objects that require extra support such as refrigerators and washing machines.

Corrugated Trays

Corrugated Cardboard Trays are basically trays to hold other objects. They are advantageous when product visibility and easy handling are of prime importance. Ideal for: food and beverage industry products such as bottled water, soft drinks, snack foods, and bulk packaged processed foods. Trays can also be used for inner packaging stacking.

Die Cut Custom

These are custom corrugated boxes designed to exact specifications depending on customers requirements. Boxes can be color printed with company name and logo, available in all styles and custom sizes. Ideal for: unique products with special requirements such as cosmetic product boxes, toy product boxes, merchandise product boxes.

Roll End Tuck Top RETT

Roll End Lock Front RELF

These are die cut unglued boxes that need to be folded when assembled. These are great for shipping narrow items. Ideal for: vitamin packaging, retail packaging, coffee packaging, tea packaging. Use for inside master pack boxes, small parts boxes, automotive parts packaging, machine parts packaging and shipping.